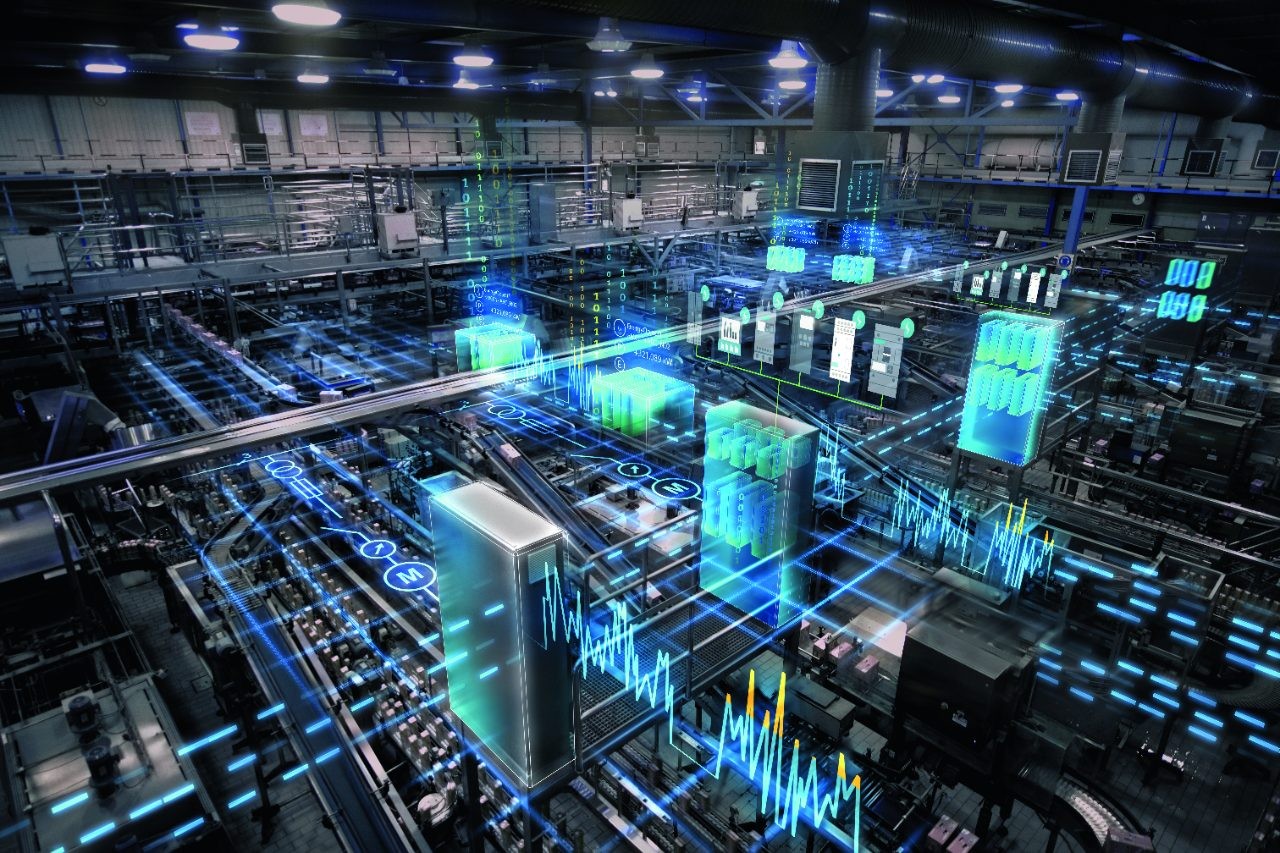

Manufacturing Execution System (MES); It is an information system that connects monitors and controls to production systems and data streams data acquisition in a factory or workshop.

The overall aim of MES is to ensure that manufacturing processes are efficient and to improve production output. This goal is achieved by monitoring and collecting real-time and accurate data about a complete product life management cycle.

With our product family, we produce solutions for facilities with the following features:

- Data Acqusition: All of the data entry, whether manual or automatic, provides a concise assessment of the entire process.

- Workforce Management: Managing the best qualities and features of employees and equipment and using them in the most advantageous areas.

- Product Tracking: With product tracking we can easily control and manage the process in production in real-time.

- Quality Control: Controlling the quality of the production process and allow changes and developments in production.

- Performance Analysis: The system analyzes the entire process and identifies areas value of the efficiency. This allows the system to move closer to the efficiency point while the process in progress.

- Maintenance Management: Inevitable maintenance that does not hinder production is planned, thus ensuring a smooth production flow.